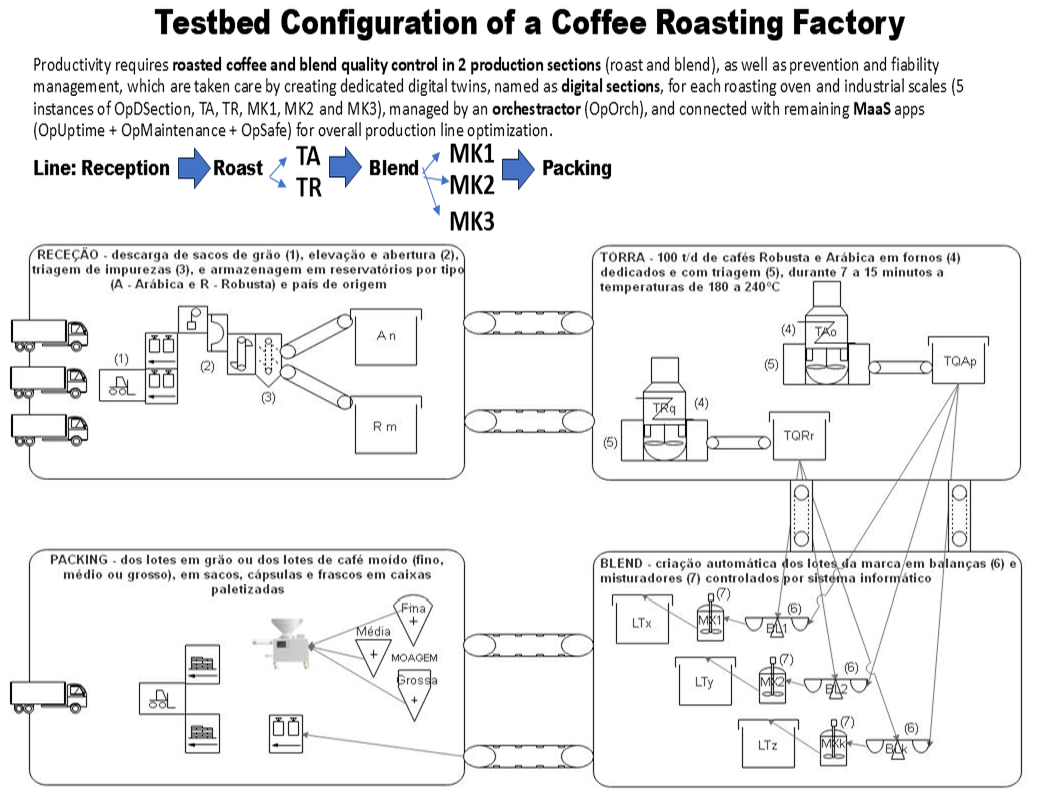

- DTs MaaS (©®) for optimal intelligent management of manufacturing in Industry 5.0 systems: OpUptime (©®), OpMaintenance ©®, OpSafe ©®, OpDSection (©®) & OpOrch (©®). which manage the production facility, fed by data from the Orchestractor (OpOrch), physical sections (OpUptime), digital sections (OpDSection), maintenance (OpMaintenance), and prevention (OpSafe).

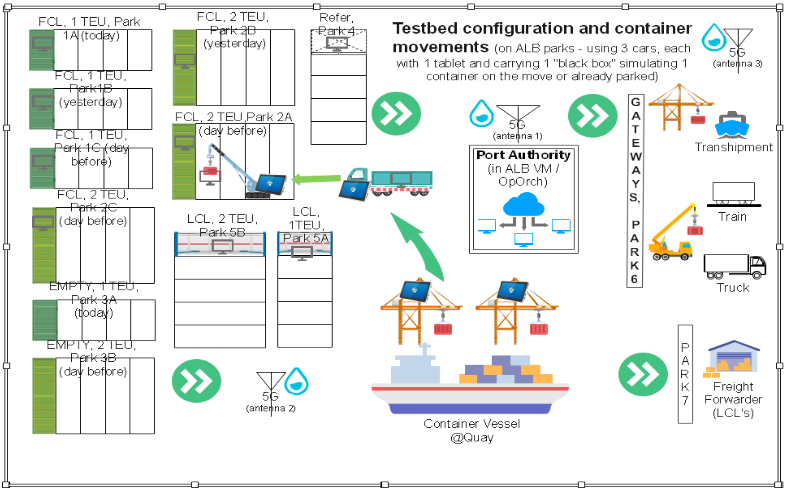

- DTs LaaS (©®) for intelligent and optimal container port maritime (or dry) management of operations:

- OpContain (©®) - optimal resource planning and container movements through port (through modelling), online execution management by 5G, detection of anomalies, with reduction on overstay and operational costs,

- OpBB (©®) - distributed app through containers and moving machines, with activities management through GNSS and 5G.

Alojamento CloudWeb, VPS (virtual private server) & Servidores Dedicados, incluindo Mail, Database e DNS, em vários Linux & Windows.

Domaín Regisreariol, Certificados, IT Projects & Cybersecurity.

Customized APPs, Online Shops & Business Websites

Graphic Design, Logos & Paginable E-Books